How Our Engineers Make Our Products

At OTPL, our best engineers make the casting process exceptional by producing high-quality custom-casting pieces. Our products display the precision, expertise, and dedication given to every product we create.

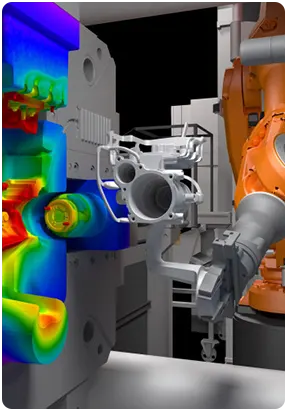

Computerized Solidification Analysis

Our process starts with a computerized solidification analysis. Using sophisticated software, Our engineers simulate and predict the molten metal behavior during the casting process.

- Identify potential defects before they occur.

- Improve the casting design for maximum efficiency.

Tool Design/Build

Our engineers move on to tool design and build after solidification analysis. This phase is critical in creating the molds that will shape our products. We invest time and expertise to get the molds that are of the highest quality.

- 3D modeling of the tool design.

- Precision CNC machining of mold components.

- Assembly and testing of the completed tool.

Inject Wax Patterns

The next step in our process involves injecting wax into the carefully crafted molds. This creates a precise replica of the final product- a wax pattern. These wax patterns set the stage for the subsequent steps in our manufacturing process.

Our engineers pay meticulous attention to:

- Wax temperature and composition.

- Injection pressure and speed.

- Cooling time and conditions.

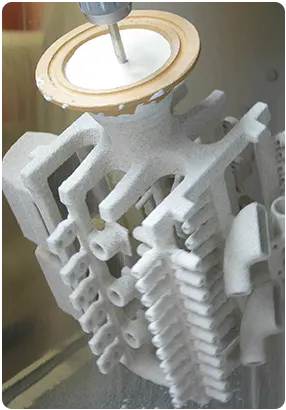

Assembly Of Wax Patterns

Once the individual wax patterns are created, our skilled technicians assemble them into larger tree structures. This assembly technique allows for efficient production of multiple parts in a single casting, improving our production capacity while maintaining strict quality standards.

This process involves:

- Carefully attach multiple wax patterns to a central wax sprue.

- Ensuring proper spacing and orientation of each pattern.

- Adding gates and vents for optimal metal flow during casting.

Shell Building

The shell-building process is where our wax patterns change into metal components. We Repeat the process multiple times to build a strong, heat-resistant shell.

This multi-step procedure involves:

- Dipping the wax assembly into a ceramic slurry.

- Coating with fine ceramic particles.

- Allowing each layer to dry.

De-Waxing

Our engineers remove the wax pattern Once the ceramic shell is complete. We prepare the ceramic mold for the introduction of molten metal. Our experts secure the integrity of the mold throughout this process.

- We Place the ceramic-coated assembly in a high-temperature autoclave.

- Rapid melting and draining of the wax, leaving a hollow ceramic mold.

- Inspect the mold for any defects or inconsistencies.

Pouring Of Molten Metal.

Our Orson engineers supervise this phase, which includes:

- Melting the chosen metal alloy to precise specifications.

- Preheating the ceramic molds to prevent thermal shock.

- Carefully pour the molten metal into the prepared molds.

- Monitoring temperature and flow rate for optimal results.

Heat Treatment

once the metal solidifies and cools, we go for heat treatment. Our process involves:

Solution treatment:

We Heat the metal to a specific temperature to dissolve alloying elements.

Quenching:

Then we Fastly cool the metal to lock in the desired microstructure.

Aging:

Holding the metal at a lower temperature to precipitate strengthening particles.

Finishing

In this stage, our engineers give final appearance to products. Our engineers and design team work together to improve the product's appearance, functions, and lifespan.

- Grinding and polishing for a smooth surface finish.

- Sandblasting for a textured appearance.

- protective coatings or decorative finishes.

- We Anodize aluminum components to increase durability and better looks.

Machining

We subject our products to precision machining to get final dimensions and features. At OTPL, we use advanced technology like CNC machining, CAD, CAM, and robotic systems for machining.

- Create complex geometries with tight tolerances.

- Add functional features such as threaded holes or mating surfaces.

- Ensure consistency across large production runs.

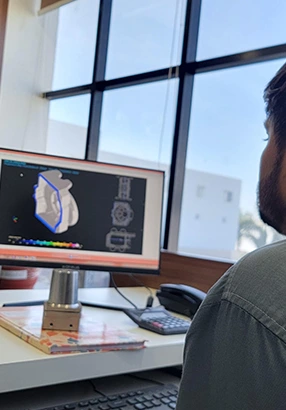

Inspection

At Orson, our inspection process is strict and all-inclusive. Our engineers are active at every stage of this process to analyze results and implement improvements to our manufacturing techniques as needed.

- Visual Inspection.

- Dimensional Measurement.

- Functional Testing.

- Non-Destructive Testing.

Packing And Dispatch

Our engineers make sure that our products reach our customers in perfect condition:

- Custom-designed packaging to protect against shipping damage.

- We use materials that are eco-friendly wherever possible.

- Clear labeling and documentation for easy identification and traceability.

- We plan Efficient logistics to lessen shipment times and environmental impact.